Will the 2030s be the Decade That Logistics Goes Fully Automated?

TalkTalk Business recently commissioned research into how UK logistics workers view the future of their industry. This large-scale survey – the details of which can be seen below – revealed some fascinating insights.

Both frontline workers and IT leaders believe that AI and automation are playing increasingly key roles within logistics – and will come to dominate the industry entirely by the 2030s. By the dawn of the next decade, said our survey respondents, the relentless drive to improve speed and efficiency will see humans moving into purely supervisory roles, their minds and bodies unable to keep pace with hyper-efficient supply chains.

In the view of logistics workers, AIs will make most of the big decisions, and robots will provide most of the labour. As an example: according to 58% of the IT leaders we surveyed, the 2030s will see driverless vehicles becoming an integral part of logistics fleets. The same number believe that the next decade will also see AIs overtaking humans as the main strategists for logistics operations – configuring warehouse layouts, automation processes and delivery routes, and optimising every aspect of supply chain management for absolute efficiency.

Will the 2030s really prove to be a tipping point for logistics, with humans making way for machines?

No drivers? No problem

First, let’s look at a technology that virtually all the frontline workers and IT leaders we surveyed believed was an inevitability: driverless HGVs.

Some respondents believed these vehicles would arrive before the end of this decade; others, sometime beyond 2040. Most, however, thought that they’d be hitting roads and making deliveries sometime during the 2030s.

The eagerness for these vehicles to enter logistics fleets is perhaps driven by memories of the UK’s HGV-driver crisis of 2021, when a perfect storm of factors – including Covid and Brexit – led to a national shortfall of 100,000 drivers.

A frantic recruitment drive reversed the decline in driver numbers: statistics for April to June 2022 showed that UK HGV drivers numbers had increased to 305,000, up from 271,000 in the first three months of the year. But the logistics industry is still braced for driver shortfalls during seasonal spikes. And the 2021 crisis showed just how rapidly and unexpectedly the available workforce could shrink.

But driverless HGVs? They don’t change careers, or retire, or return to their country of origin. They don’t get ill, they don’t need rest, and they don’t take holidays. So when will they get here?

According to a future-gazing report by the McKinsey Centre for Future Mobility, autonomous HGVs are likely to be rolled out in four separate phases, with additional autonomy being granted to the vehicles at each phase.

In the first phase, a technique called platooning will be deployed. In platooning, a fleet of AI-driven trucks closely follows a human-driven lead truck on motorways. These autonomous trucks will not be truly driverless: each will have a human driver who will take over when the truck leaves the motorway – because while it’s relatively easy for an AI to navigate motorways, the knotty streets of, say, Reading city centre are more challenging.

The second phase will see a human driver in the lead truck only, with autonomous trucks close behind. By the third phase, even these lead trucks will be entirely autonomous – although a human driver will still be necessary for smaller roads and loading bays. The McKinsey report states that this third phase would result in cost savings of around 20% for fleet operators.

The fourth and final phase – which the McKinsey report estimates occurring somewhere between 2030 and 2040 – involves entirely autonomous HGVs operating at scale, across the UK. How quickly this occurs may depend, in part, on how far the national infrastructure has developed for driverless vehicles of all kinds.

The International Transport Forum predicts that, by 2030, demand for truck drivers in Europe and the US will be reduced by 50–70% due to automation. Such a dramatic shift may seem inconceivable right now, but this forecast goes to show just how profound the introduction of this technology will be and how rapidly it’s expected to be adopted.

Quick, quicker, quickest thinking

Across every sector, AI adoption is accelerating. According to a MarketsandMarkets report, the AI market will be worth $190 billion (£153 billion) by 2025. By 2030, AI technology is predicted to add $15.7 trillion (£12.7 trillion) to global GDP.

And in the logistics industry? A report by Meticulous Research forecasts that the global market for supply-chain AI will reach $22 billion (£17.8 billion) by 2027 – a growth of 45.3% from where it stood in 2019. Meanwhile, McKinsey predicts that “an entirely new logistics paradigm is coming into view, as AI takes over the many repetitive activities that logistics companies perform.”

AI is not only predicted to take control of these repetitive tasks – choreographing warehouse robots in hyper-efficient, 24/7 ballets – but will also be increasingly called upon to make big-picture decisions. By analysing big data gleaned from supply chains, AIs can advise their human masters on ways that operations can be sped-up and streamlined – by opening up new warehouse locations, for example, or shifting stock from one area of the country to another. AIs will provide valuable insights that human workers – working with limited datasets and analytical capabilities – simply won’t be able to see.

Companies such as H20.ai, C3.ai and Alloy.ai are making inroads into the logistics and manufacturing industries with AI models that gather data from a variety of sources – including sensor networks, enterprise applications and third-party data – to bring supply chain management into the Fourth Industrial Revolution.

In our survey, both frontline workers and IT leaders agreed that AIs would be increasingly advantageous to logistics operations in the years leading up to 2030. Across both cohorts, 58% predicted that AIs would be redistributing products to more optimal warehousing locations around the UK and Europe; 61% predicted AIs would be reconfiguring warehouse layouts to optimise space; 63% predicted AIs would be streamlining processes for human workers; 65% predicted AIs would be streamlining automated processes; and 69% predicted AIs would be reconfiguring warehouse layouts to optimise efficiency.

The robots are coming

Robots already play a key role in most major enterprise-level logistics businesses. The sector has led the way in automation, with a combination of autonomous mobile robots (AMRs), AIs and sensors – including cameras, radar, and LiDAR – making warehouses increasingly efficient. These logistics robots have undeniably displaced human workers, but they’ve also made warehouse work less repetitive, back-breaking and hazardous for the humans that remain.

And the march of automation in supply chains is only set to continue. IDTechX forecasts that the market size for logistics is set to be nine times larger in 2032 than it was in 2021. McKinsey, meanwhile, predicts that “by 2030, we expect to see fully automated high-rack warehouses, with autonomous vehicles navigating the aisles. Managers with augmented-reality goggles will be able to ‘see’ the entire operation, helping them coordinate both people and robots. Warehouse-management systems will keep track of inventory in real time, ensuring it is matched to the ordering system. 3-D printers will crank out spare parts made to order.”

Frontline workers who responded to our survey were resigned to the fact that robots would be displacing them in large numbers. 76% believed that, eventually, warehousing tasks will “mostly” or “almost entirely” be performed by robots. Only 24% predicted that warehouse workforces were destined to be “mostly humans, assisted by robots”. No respondents believed that, come the 2030s, warehouse teams would be “almost entirely human”.

Getting ready for what’s next

These tech-driven evolutions will happen incrementally rather than instantaneously. So it’s essential to get your business prepared now for what comes next. With a strong, scalable and resilient network in place, your infrastructure is ready to handle everything from automation to big-data analytics.

With TalkTalk Business, your network is designed around you. You’ll have the speed, flexibility and rock-solid resilience you need to provide exceptional customer service – and the data you need to future-proof your business.

2030 is fast approaching – so get yourself ready with TalkTalk Business.

Learn more about how logistics is evolving – and how these changes are viewed by industry insiders. Read our exclusive whitepaper: AI, Automation and Where Logistics Goes Next.

About the research

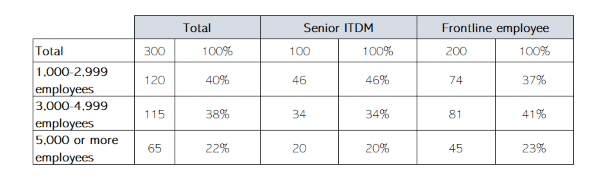

In September 2022, we commissioned a survey by Vansorn Bourne of 300 senior IT decision-makers and frontline employees in business sizes ranging from 1,000-2,999 employees to those with 5,000 or more.